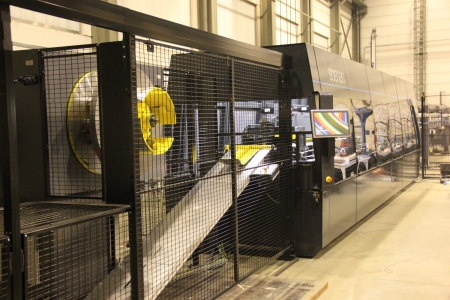

CUT-TO-LENGTH & STACKING LINES

THE AUTHORITY IN CUTTING & STACKING LINES

We deliver state-of-the-art equipment with the highest quality, accuracy, and performance standards at a very competitive price. Our high-speed lines combine extraordinary speed and accuracy for today's market.

.jpg)

| Line Type | Width range (mm) | MAX.Length (mm) |

| TRL250 | 40 - 250 | 1350 |

| TRL400 | 40 - 440 | 2500 |

| TRL600 | 60 - 660 | 3500 |

| TRL800 | 80 - 880 | 4000 |

| TRL1000 | 100 - 1020 | 5000 |

Transformer Cutting

Soenen is one of the market leaders for silicon steel cut-to-length lines for transformer lamination. The sequence of cutting, notching and stacking is a complicated production process due to the high speeds, the start-stop movements, and the use of very delicate material (silicon metal sheets 0.18 – 0.5 mm thick). But the outcome is always the same - laminations impeccably cut with no sheet damage and no burr.

Special Cutting

The demand for cutting lines in the service industry is steadily growing. Especially the automotive sector has an important need for precut trapezium-shaped plates. Our production lines are equipped with electric swivel shears, which cut the steel sheets into precut plates. We manufacture lines that can handle 120 meters of coil per minute and accurately measure to 0.1 mm. Soenen has built cutting lines for Corus (now Tata Steel) and ArcelorMittal.

E-Stacking

In order to make the manufacturing of a transformer more efficient, flexible and accurate we developed two different E-stacking concepts that will revolutionize the transformer market: the Soenen in- and off-line E-stacking systems. Both systems are fully automatic and overall faster.

Our in-line system is a high precision placing unit, positioned behind a new or existing core cutting line. Its stacking capacity is in accordance with the cutting speed of the line. The offline E-stacker is a compact stand-alone pick and place unit. Sheets are picked from irregular stacks and automatically placed in an E-shape. In order to detect out of range tolerances the gaps between the sheets are scanned.

.png)