3 in 1 Busbar Center SLB 125

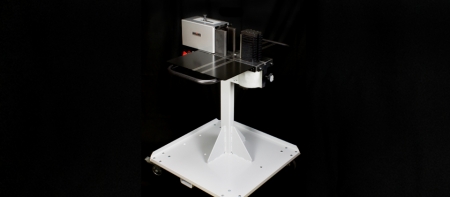

Basic unit on trolley SLB 125

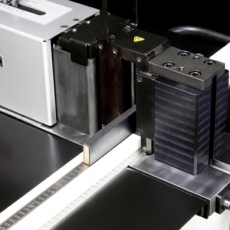

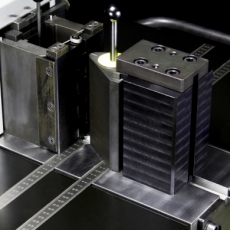

The unique SLB 125 3in1 busbar center guarantees effortless cutting, punching and bending of copper busbars up to 125 x 13 mm (4"x1/2"). Ideal for the switchgear work shop or at site the base unit transforms into a cutting, punching or bending machine within seconds.

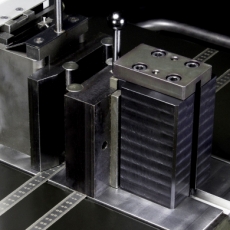

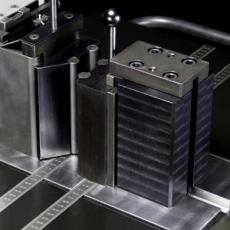

Performance is comparable with stationary copper busbar machines, e.g. cutting of a 120 x 10 mm (4 3/4"x 3/8") copper busbar, in just 6 sec.. Punching of copper busbars is quick, effortless and without any pre-marking of the busbar. Fixed or adjustable guide plates will allow instant punching of common switchgear hole pattern. For bending of copper busbars a broad range of bending accessories will allow tight and specific bending curves as requested in modern switchgear and circuit breakers. Even processing of flexible copper busbar is possible with great safety and cutting edge quality.

Busbar fabrication from a single mould:

Precise, simple and quick.

Advantages

-

- Especially robust and stiff frame

- Lightning-swift tool changes with a minimum of manipulation

- Very high quality cutting, bending and punching

- The 150 bar low-pressure system ensures a long service life and very fast cycle times

- Busbars bent accurately up to 120° – very accurate reproducibility of the set angle

- For busbars up to 125 x 13 mm

- Accessories for flexible busbars available

Technical specifications

| Height | 1,145 mm |

|---|---|

| Depth | 750 mm |

| Width | 750 mm |

| Weight | 180 kg |

| Operating pressure | 150 bar |

| Force | 180 KN |

| Power rating | 1~ 230 V/50 Hz |

| Voltage | 0.75 KW |

| Cutting max. | max. 125 x 13 mm 250 N/mm2 |

| Punching max. | max. Ø 6 bis 21 mm |

| Bending max. | max. 125 x 13 mm 250 N/mm2 |

SLB 125 Kombigerät 3 in 1 Complete System Ref.No. 39659

| Power Pack HA3 | Ref.No. 33340 |

|---|---|

| Cutting Tool | Ref.No. 31242 |

| Bending Tool | Ref.No.31243 |

| Punching Tool | Ref.No. 30980 |

| Guiding Plate | Ref.No. 31890 |

| Tool insert 9.0 mm dia | Ref.No. 31161090 |

| Tool insert 11.0 mm dia | Ref.No. 31161110 |

| Tool insert 14.0 mm dia | Ref.No. 31161140 |

| SLB 125 Basic unit on trolley | Ref.No. 40070 |

Accessories

Large-Step-Bending-Tool Ref.No. 31646

For quick and 100 % parallel step bends on up to 120 x 10 mm busbars.

Step = 37 mm wide and 25 mm high.

Small-Step-Bending-Tool Ref.No. 31425

For quick and 100 % parallel step bends on up to 80 x 8 mm busbars.

Step = 21 mm wide and 18 mm high.

Supplementary-Bender-SLB Ref.No. 31636

The L-Bending-Tool will allow short “L”-bends with only 25 mm leg.

SLB 125 standard setup will allow 45 mm as shortest leg.

Special-U-Bender Ref.No. 42430

Tight U-bends are often a problem on multi-purpose copper busbar machines. With our special U-Bending-Tool you can bend your copper busbar as tight as 60 mm (2.4") inside. With this very tight copper busbar geometry your switchgear will always be "in shape".

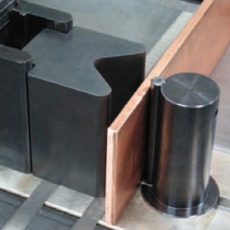

Cutting Cartridge Ref.No. 45445

For cutting flexible copper busbars up to 120 x 10 x 1 mm our brand new SLB 125 Cutting Cartridge is available.

With this all new cartridge cutting becomes easy, safe and of outstanding quality. The problematic copper sawing and related dust and chips are a thing of the past. Regardless of cutting insulated or stripped copper bars, subsequent processing will be trouble free. For punching flexible busbar we recommend using the special punching dies including stripper plate.

.png)