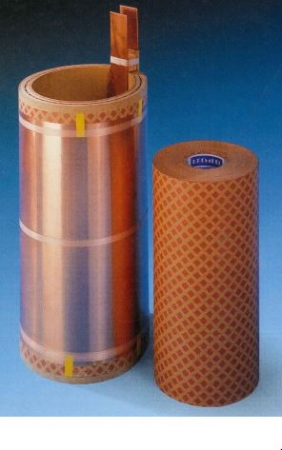

กระดาษฉนวน - DPP

Presspaper with partial resin coating P.4.1A according to IEC 60641-3-2

- KREMPEL-DPP is a natural-coloured presspaper made of 100 % unbleached sulfate cellulose with

double-sided diamond dotted, still reactive resin coating. The coating quadrats of KREMPEL-DPP

have a lateral length of 9.5 mm and a spacing of 6.35 mm. Approx. 36 % of the total surface of

each side is thus printed with epoxy resin. The quadrats are arranged so that their diagonals are

parallel and perpendicular to the machine direction of the transformer presspaper.

- KREMPEL-DPP is primarily used as layer and winding insulation in the LV and HV coils of transformers.

After curing, the partial resin coating bonds the electric conductors with the insulation, which

brings about the mechanical consolidation of the coils. In this way the radial and axial forces that

arise in the event of short circuit can be safely controlled.

- Coils manufactured with KREMPEL-DPP can be quickly and safely impregnated with insulating oil

(transformer oil and silicon oil). This minimizes the risk of partial discharges following inadequate

impregnation.

- Our specially developed resin composition for KREMPEL-DPP offers short curing times, high binding

strength and excellent long-term storage stability.

- Upon request, KREMPEL-DPP can also be manufactured on two-layer bonded, thin presspaper.

Extra compact coils are possible with this version.

- KREMPEL-DPP can also be supplied in the special “Thermally upgraded” version (name: DPP TU). Here the

thermal ageing process of the presspaper is delayed by adding a small quantity of a nitrogenous additive.

- KREMPEL-DPP can be supplied as an original roll or narrow roll.

.png)